From Log to Living Room: Will Walker of Wm. Walker Co.

Customer Feature Stories

Will Walker is a furniture maker and sawyer; however, upon hearing his story, entrepreneur is also a very fitting title. Will's creative spirit and entrepreneurial mindset have driven him to identify and pursue business opportunities which span multiple industries. He has even built a substantial following on YouTube where he educates viewers from around the world while demonstrating his craftsmanship, expertise and passion.

Will grew up helping his dad, a general contractor, build houses, where he gained valuable skills that would come in handy down the road. In high school, he also developed a passion for photography. He attended art school at Virginia Commonwealth University where he fostered his craft for photography. He spent his free time in the wood shop. After apprenticing with a photographer in Richmond, Will came back to his hometown of Charlottesville, Virginia to begin his photography business in 2006, where he photographed weddings, portraits, stories for newspapers, corporate events and more.

Later, Will met his wife and decided to build a house on the family farm in the beautiful countryside of Albemarle County. Since Will still enjoyed woodworking, when he built his home, he knew he wanted to add a workshop. When their first child was due to be born, he took a break from event photography weddings around the due date. With a little more free time on his hands, Will decided to stand on the other side of the camera for a change and began documenting the process of building his shop and posting the videos to YouTube. He thought this might drum up some local business, but he soon learned that people around the world were interested in what he had to say and eager to follow his journey. And so, the adventure of Wm. Walker Co. began in 2015.

Since 2015, Will's following has grown to nearly 80,000 subscribers on YouTube, and more than 11,000 followers on Instagram. Find him at @wmwalkerco on both (also linked in previous center). Plus, check out one of his recent YouTube videos at the bottom of this blog article in which he shares his story and creates a three-legged plant stand out of Cherry and Maple using staked furniture techniques.

As Will dove headfirst into furniture making, he started sourcing hardwoods and quickly discovered that they were often difficult to acquire. He began working with community members who were sawing their own wood and before long, he had the opportunity to purchase his very own sawmill in 2020. This enabled Will to source logs that had fallen during storms, trees that were destroyed by pests (including ash trees which have been destroyed by the Emerald Ash Borer across Virginia and other states) and trees that people were having removed and would otherwise have been burned. At this point, Will began to see that there was a great deal of potential in this industry.

“I started milling and realized that there was a whole lot of interest in the wood that I was milling in addition to the furniture that I was making,” Will reflected. He began selling his own hardwood lumber from these salvaged, mostly fallen or unwanted trees and was met with great demand.

As demand rose, so did the need for a larger sawmill. Will began looking into larger capacity sawmills but needed a place to station the mill, so he turned to his friend, Taylor Pippins. Taylor is a farmer who offered to house the larger mill on his property to help Will in his endeavors. As Will researched his options for a larger sawmill after the height of the pandemic, he learned the wait times were tremendous (upwards of one to two years) and financing options were slim from traditional banks. Will's friend, Taylor, has been a Farm Credit customer-owner since he was 22 and suggested Will reach out to the cooperative. Will gave the Charlottesville branch a call, explained that he was looking to purchase a used sawmill (pictured below) and Farm Credit made it happen.

“Farm Credit made the process easy and painless. They understood the implements and equipment that we need,” said Will. Will credits the speed of financing he received from Farm Credit in the summer of 2023 as being key to his operation and being able to get up and running with the new sawmill. Following the purchase of his new sawmill, Will had ability to mill logs that are up to 21 feet long and make 48 inch cuts, whereas he could only mill logs that were 14 feet long and make 21 inch cuts with his original mill. The new mill is also mobile, so Will and Taylor can take it to farms or other rural properties to pick up the timber where it is.

“I’m pretty passionate about sustainably harvested hardwoods and taking the wood through its lifecycle from log to living room,” said Will. He loves bringing his clients along on the journey, showing them where the tree came from, what species it is, why it came down and then sharing the process of cutting, air-drying, kiln-drying and finally processing to create their dream table or cabinet. The business is split between custom commissioned furniture under the Wm. Walker Co. label and the sawmilling process, which includes lumber sales to other furniture makers and woodworkers, which falls under Ursa Timber, a partnership between Will and Taylor. The custom pieces of furniture have a longer timeline to complete, so the lumber sales originated as a way to make supplemental income during the longer build process of the custom furniture (which can take 14-16 weeks in a perfect scenario, from tree in the ground to table in a home). However, the hardwoods Will harvests and mills have become so popular that those projects now take up about 60% of his time, while the custom commissions take up roughly 40%.

Will works with a local friend and fellow sawyer to source other sustainably harvested lumber for his custom commissioned projects when he can’t meet those needs with his own supply. His friend also has a kiln where the lumber is dried to the correct moisture content and then stored on the property in an old barn that has been retrofitted as a wood storage facility. Hardwoods increase in value throughout the drying process, so the longer the boards are able to dry, the more valuable it will be, in theory.

Through networking in the woodworking community, Will has found different buyers who are interested in different products, from freshly cut, green lumber to a completed piece of furniture. Will has repeat customers who return time and time again because they value the quality of the lumber. Future plans for Will and Taylor include adding their own kiln, storage outbuildings and retail barn to serve as a showroom when clients visit to pick out wood for furniture pieces or to purchase for their own projects.

Will shared, “Right now I’m working on a solid walnut dining table for a couple in Charlottesville. They were able to come out and pick the lumber, and as we cut the boards for the tabletop, we kept them in sequence. So as you open it up, it is what’s called a ‘book match,’ which means the wood mirrors itself across the tabletop.”

When asked what his favorite aspect of his business is, Will answered with a word he learned in art school, “Gestalt is when the sum of all of the added parts are greater than the individual parts themselves. It’s the idea of taking a tree that would otherwise rot in the ground or be burned for heat and giving it a second life as a beautiful, functional piece of furniture.”

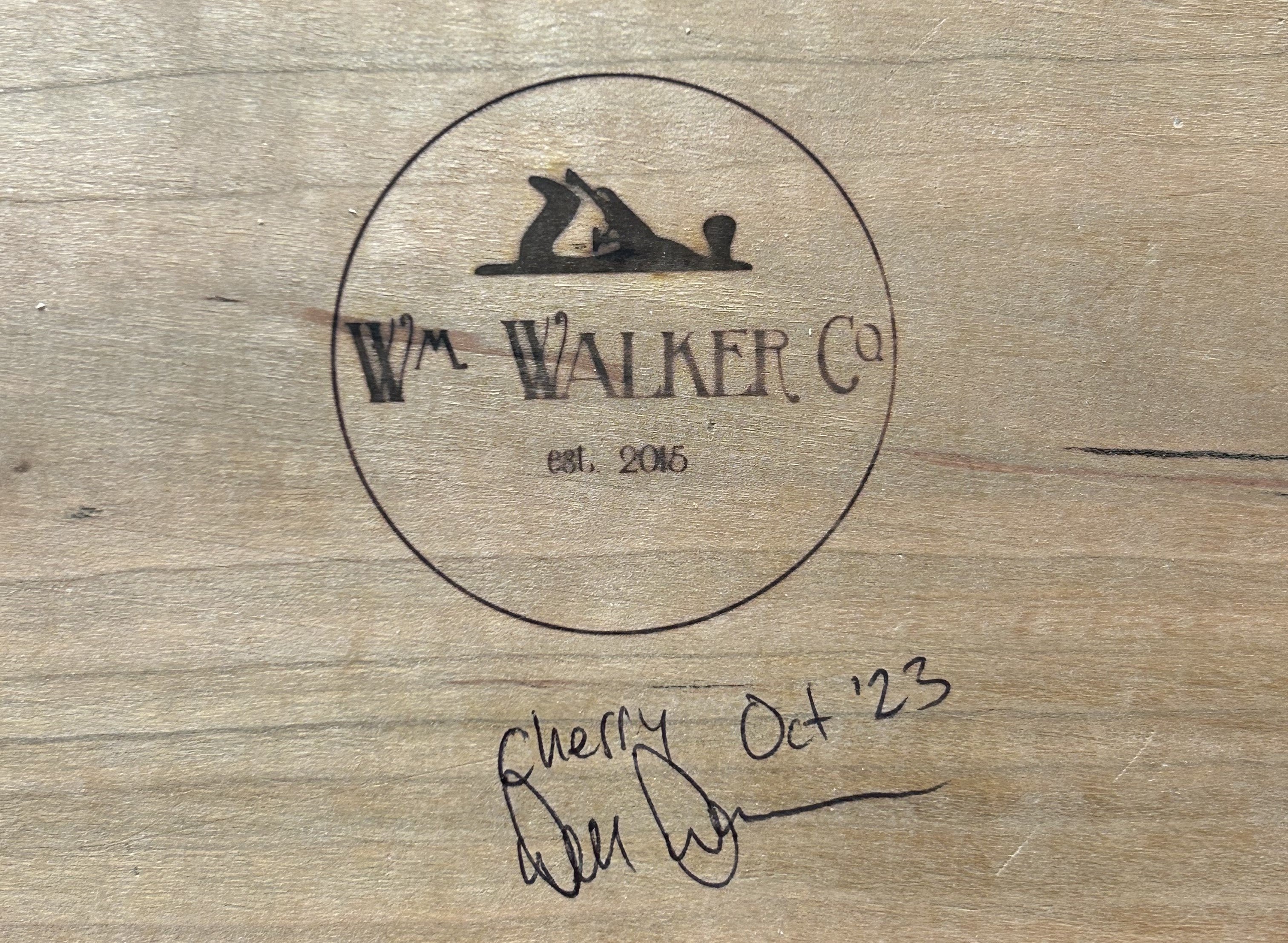

“When Will finishes a piece, he burns his brand into the underside of it, then he’ll sign it, date it and add the wood species, as well,” said Taylor. “One thing that resonates with me about what Will is doing is that he is crafting these quality pieces that will hopefully outlive him and leave a legacy for the generations to come.”

Will and Taylor’s advice to young people looking to break into the woodworking or sawmill industry is to find someone who knows a lot and is willing to share that knowledge. “Listen to people who have done it for a long time, and try to love what you do. If you’re not having fun, it’s not worth doing,” said Will.

Will’s dad served as a great mentor during his formative early years when Will helped build houses. Will also worked under a cabinetmaker when he was a young photographer getting started who taught him everything there was to know about cabinetmaking and served as a valuable mentor, as well. Will even enjoys learning from the “old masters,” furniture makers from centuries ago, by reading books and studying their craft. Many pieces from centuries ago are still around today, so those makers knew what they were doing, and some of those methods can still be put into practice today. If you ask questions, listen to the answers and are willing to get your hands dirty, older generations love to share their wisdom – and there is much to be gained from their experiences.

Learn more about Wm. Walker Co.: https://www.wmwalkerco.com/

This feature story was published in the December 2023 Leader Magazine. Access the full magazine (digital version) HERE.